When it comes to selecting a plastic cage to be used in a particular application (like Gnotobiotic facilities), there are many questions that need to be asked. Depending on the methods and environment of use, a different priority is given to certain classes of characteristics that the choice must include.

Among these, the most important are:

• Thermal resistance

• Resistance to the surrounding environment (normally defined as “chemical resistance”)

• Aesthetics (ability of the polymer to assume certain shapes, to be transparent, …)

• Mechanical resistance (ability to withstand mechanical stresses, states of stress or strain imposed or periodic stresses)

• Resistance to UV rays (in some cases, overexposure to light, and therefore to UV rays, can cause degradation of the polymer)

One of the main requirements for an animal cage is the autoclavability.

It must be able to undergo autoclave cycles without showing significant deformations or degradations over time. It must therefore have good thermal and dimensional stability (it is necessary that its dimensions remain stable since it must be located in a specific rack).

Moreover, it must not undergo degradation due to contact with the most common sterilizing detergents.

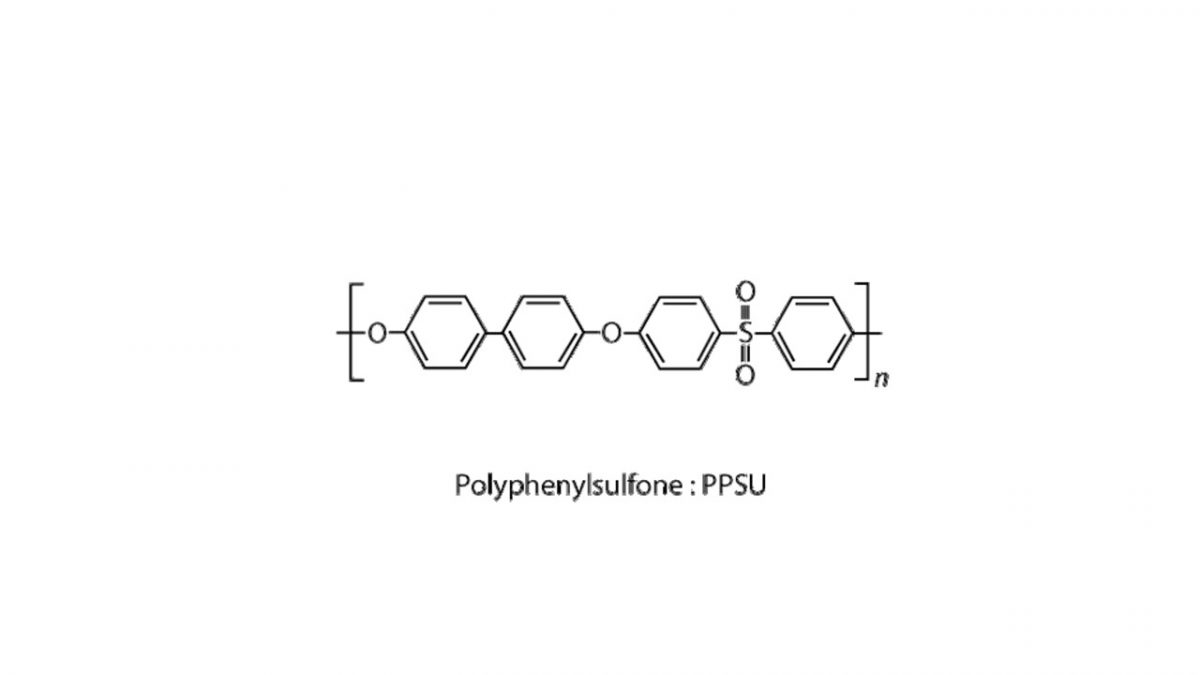

For these reasons, Polysulfone (PSU) and Polyphenylsulfone (PPSU) are the most common plastics used inside the facilities.

When one or the other plastic is recommended? Both are transparent plastics and can withstand high temperatures. In fact, both can be autoclaved at 134 ° C.

However, Polyphenylsulfone has not only excellent thermal resistance and dimensional stability, but also very good chemical and impact resistance.

PSU is the common plastic for IVC cages inside standard room or SPF facilities, while PPSU is recommended when a higher level of safety is required, like for gnotobiotic or germ free mice. So the choice should evaluate both the maintenance planned for the cages but also the importance of the experiments.

Recent Articles

- Gnotobiotic facilities: writing inside isolators 4 April 2022

- Germ-free cage sterilization 24 January 2022

- Microbiota and its importance in aging 25 October 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 2) 27 September 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 1) 30 August 2021

DVC – Digital Ventilated Cage for digital vivarium

The DVC® is capable to provide novel insights and enhance animal welfare checks thanks to the automatic data collection directly from the cage level. Specifically designed DVC® board enables different benefits for the researchers and vivarium people.