The use of IVCs cages in the context of the maintenance of Germ-Free or flora associated rodents required, on the part of animal care specialists, an effort in the development of specific procedures for the safe microbiological management of these particular animals. There is an evident need to operate in sterile conditions at delicate moments such as the opening of the IVC cage to allow the animal handling procedures necessary for both cage changes and experimental activities.

The choice to use class II BSCs was undoubtedly optimal because, thanks to their flexibility, such equipment allows the “content” (cage and animals) and the operator to be protected at the same time. Despite this, the introduction of a cage on the work bench of a Biosafety Cabinet can lead to contamination of the working environment itself. In fact, the external surface of the cage cannot be sterile as it is constantly exposed to the environment of the room when placed on its ventilated rack.

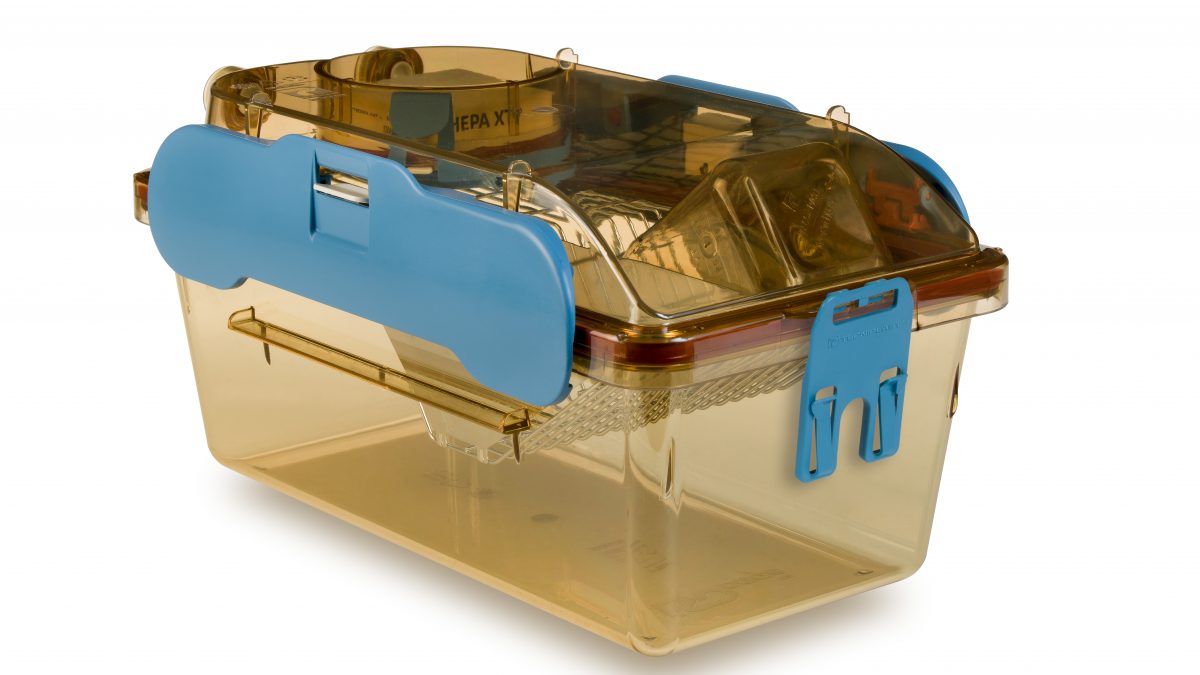

At least two solutions have been developed to allow optimal decontamination of the external surfaces of the specific IVCs purposely designed for biocontainment and bioexclusion. The first is that of the dunk-tank, thanks to which the cage undergoes a complete timed immersion in a suitable disinfectant and the second is that of manual decontamination with disinfectant spray. The first solution (dunk tank) can only be applied with perfectly hermetic cages (Isocage) while the second can also be used with less performing cages.

This procedure takes place with the animals inside the cage, which is in static conditions and therefore must take place in a reasonably short time to ensure the welfare conditions of the animals contained therein. The question that arises spontaneously, however, is: which disinfectant should we use to obtain a decontamination of the external surfaces of the cage so as to ensure a low-risk management of the same once introduced inside the BSC?

Recent Articles

- Gnotobiotic facilities: writing inside isolators 4 April 2022

- Germ-free cage sterilization 24 January 2022

- Microbiota and its importance in aging 25 October 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 2) 27 September 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 1) 30 August 2021

DVC – Digital Ventilated Cage for digital vivarium

The DVC® is capable to provide novel insights and enhance animal welfare checks thanks to the automatic data collection directly from the cage level. Specifically designed DVC® board enables different benefits for the researchers and vivarium people.