Another total decontamination (surface + interior parts) method for Biosafety Cabinet (BSC) in a gnotobiotic facility is the formaldehyde fumigation (recommended in the main international standards EN12469, NSF49 and AS2252.4) to provide a 6log killing of biological agents.

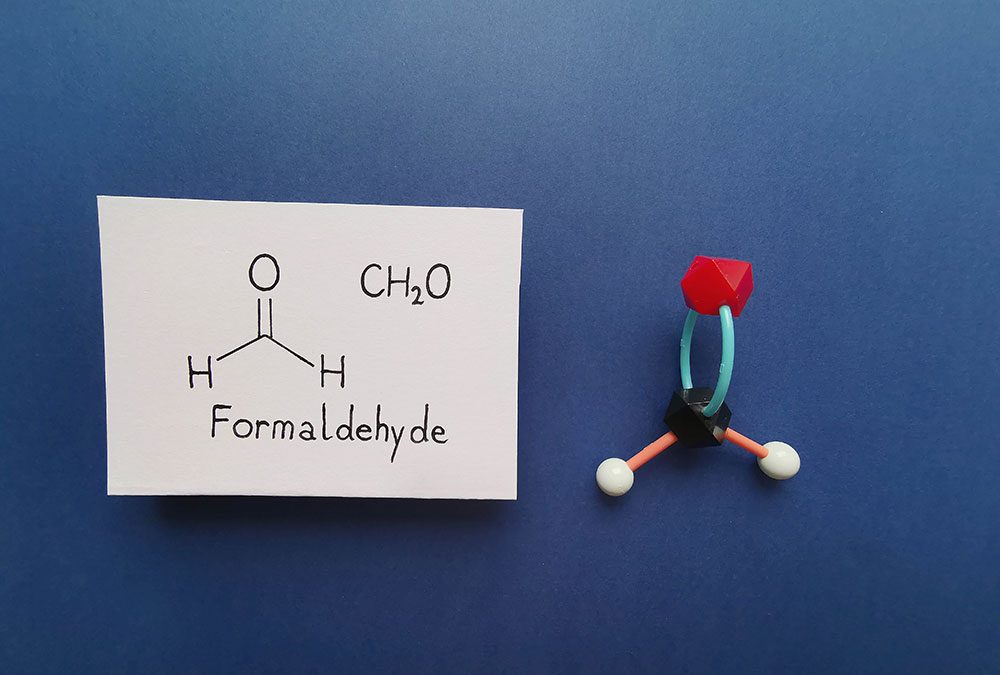

Formaldehyde (CH2O) generally refers to the gaseous form of the chemical. Formalin refers to the aqueous solution, whereas the solid form is known as paraformaldehyde.

Over the years the use of formaldehyde gas had been the only process considered validated for BSC decontamination but, due to its potential carcinogenic effects on human health and environmental impact, in some countries formaldehyde has been banned or restricted.

Mostly, the decontamination is performed using formalin gas by either vaporizing 36% formalin and ammonia solution or by depolymerization of solid paraformaldehyde (with concentration of ~ 8000 ppm) and ammonium bicarbonate (NH4HCO3) in a formalin vaporizer placed inside the BSC work chamber.

Water is diluted into the formalin container to increase the decontamination area humidity so as to be above 60 / 65%. The Biosafety Cabinet must be covered with a plastic bag and sealed along the entire lower outer perimeter of the cabinet.

This process of decontamination with formaldehyde and neutralization with ammonia may leave a residue on the surface that must be hand-cleaned.

The entire process takes 15-18 hours to complete and access to the room, while the cycle is running, is not recommended.

Recent Articles

- Gnotobiotic facilities: writing inside isolators 4 April 2022

- Germ-free cage sterilization 24 January 2022

- Microbiota and its importance in aging 25 October 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 2) 27 September 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 1) 30 August 2021

DVC – Digital Ventilated Cage for digital vivarium

The DVC® is capable to provide novel insights and enhance animal welfare checks thanks to the automatic data collection directly from the cage level. Specifically designed DVC® board enables different benefits for the researchers and vivarium people.