Shipping germ-free or gnotobiotic animals is a challenge with many variables to control. Currently the most common option for shipping these animals is the flexible film style shipper that will connect directly to the port of a flexible film isolator. However these shippers can be expensive and limit the number of animals to 3 cages within the shipper. Resterilising used shippers is also expensive and sometimes the ring inside the shipper can fail upon resterilisation due to the cardboard getting wet and losing rigidity.

Whilst there are existing smaller reusable options for shipping Gnotobiotic mice, these require return shipment the sending facility. In Australia, due to the large geographical distances between facilities we needed a disposable option that was inexpensive.

Together with the Gnotobiotic Facilities at WEHI and SAHMRI in Australia, the TRI Gnotobiotic facility has refined the use of a disposable IVC cage to enable shipping germ-free mice between facilities in Australia.

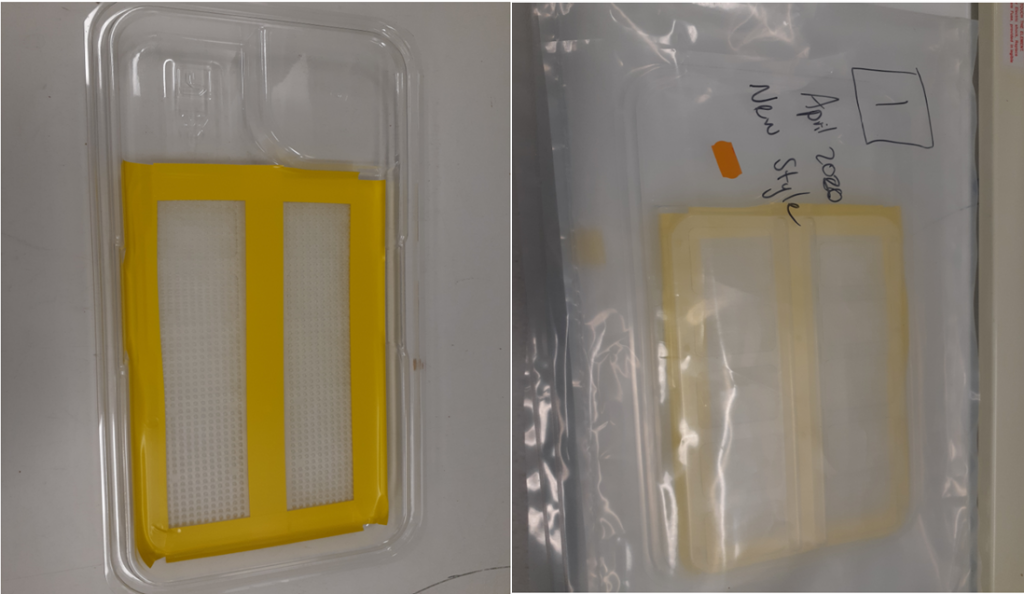

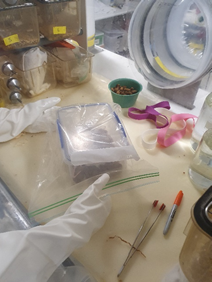

The filter top of the cage is taped with vinyl tape across all seams between the filter and the plastic top. It is then double sealed in polypropylene bags using a heat sealer, and gamma irradiated at 50kGy to sterilise. The base of the cage can be cold sterilised prior to packing in a Biological Safety Cabinet (BSC).

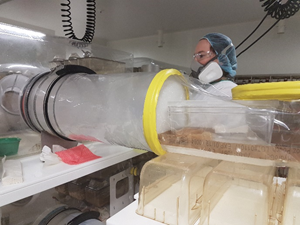

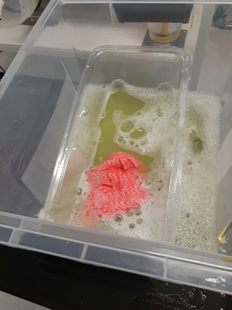

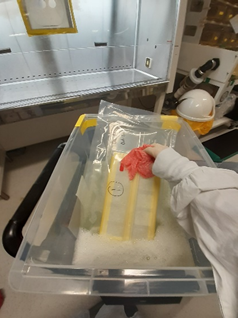

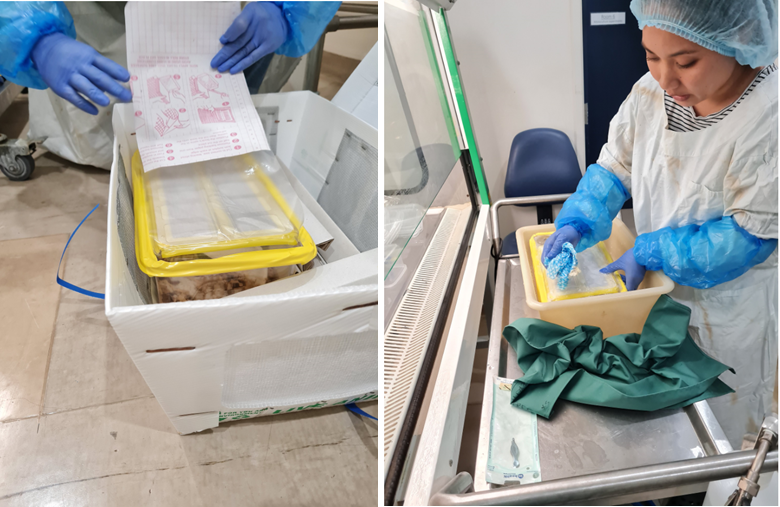

When ready to ship, supplies are dunked into the BSC (disposable cage bases, bagged irradiated lids and vinyl tape, autoclaved packs of food and bedding, sterile gel packs). After a UV cycle, germ-free or Gnotobiotic animals are transferred to the BSC from isolators in sealed sterile containers, and dunked into the cabinet.

Utilising strict aseptic technique the animals are packed into the sterile cages, the lids are taped to the bases using irradiated tape. Packed cages are then double contained in an autoclaved outer shipper and are ready for transport.

The receiving facility will utilise glue backed plastic to tape over the filter part of the lid, allowing the cage to be fully dunked into a BSC. Animals are carefully transferred into sterile positive pressure Gnotobiotic cages, or can be transferred into isolators.

It is worth noting that the success of this method does rest on excellent aseptic technique in the biosafety cabinet, and a relatively short shipment duration (< 48 hours). For longer durations we would still recommend the standard flexible film shipper. We have found this method to be a reliable and cost-effect solution to shipping within Australia.

Emily Duggan

Senior Gnotobiotic Facility CoordinatorTranslational Research Institute

Recent Articles

- Gnotobiotic facilities: writing inside isolators 4 April 2022

- Germ-free cage sterilization 24 January 2022

- Microbiota and its importance in aging 25 October 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 2) 27 September 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 1) 30 August 2021

DVC – Digital Ventilated Cage for digital vivarium

The DVC® is capable to provide novel insights and enhance animal welfare checks thanks to the automatic data collection directly from the cage level. Specifically designed DVC® board enables different benefits for the researchers and vivarium people.