All Class II, Type A2 Biosafety Cabinets are designed to recirculate their HEPA filtered exhaust air back into the laboratory. Certain applications such as working with odorous products or volatile toxic materials will require the connection of the Biosafety Cabinet to an exhaust system. When decontamination or full fumigation of safety cabinets should be carried out with hight frequencies, in accordance with the experimental protocol, this becomes one of the main reasons exhausting a cabinet to atmosphere.

Ducted cabinets will drastically decrease the aeration time for all methods. It can be as fast as 5-10 minutes with formaldehyde or chlorine dioxide gas based upon 500 m³/h (300 CFM) exhaust rate and 2 m³ (85 ft3) BSC volume and can be 30 minutes for vaporised H2O2. Ducted cabinets also bring up concerns for the damper that isolates the BSC. Is the damper sealed? If the damper is not fully closed or sealed, the concentrations will drop in the BSC and therefore cause an ineffective decontamination cycle.

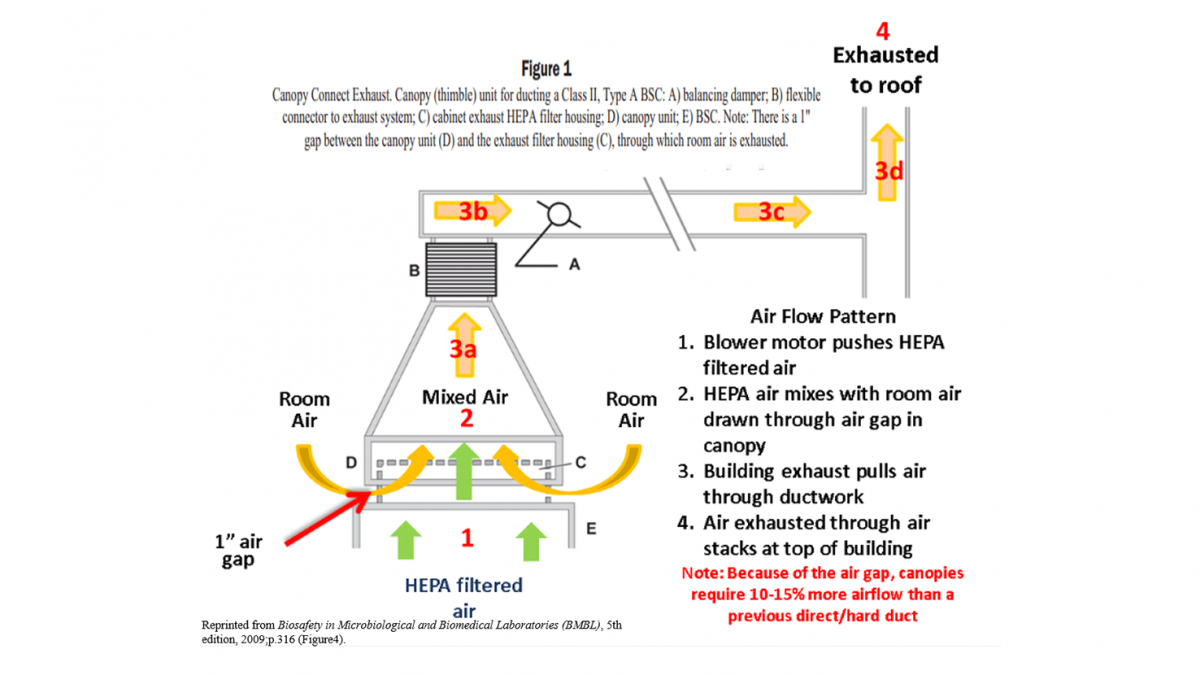

Canopy Transitions, sometimes referred to as a thimble or air gap exhaust transitions, provide an air gap between the exhaust efflux of the BSC and the transition. The air gap essentially insulates the BSC from potential variations of airflow in the facility exhaust system, particularly if multiple BSC’s are connected to the same exhaust blower system.

By-pass motorized dampers which open and close according to cabinet usage, allow the exhaust duct connection from BSC to HVAC system with room pressure stabilization.

Recent Articles

- Gnotobiotic facilities: writing inside isolators 4 April 2022

- Germ-free cage sterilization 24 January 2022

- Microbiota and its importance in aging 25 October 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 2) 27 September 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 1) 30 August 2021

DVC – Digital Ventilated Cage for digital vivarium

The DVC® is capable to provide novel insights and enhance animal welfare checks thanks to the automatic data collection directly from the cage level. Specifically designed DVC® board enables different benefits for the researchers and vivarium people.