Last chapter of the series dedicated to ducted cabinets and what are the important things to know about them when setting up an animal facility.

If the exhaust system malfunctions, does the user understand its impact on the Biosafety Cabinet (BSC) ability to maintain personnel and environmental protection, i.e. containment?

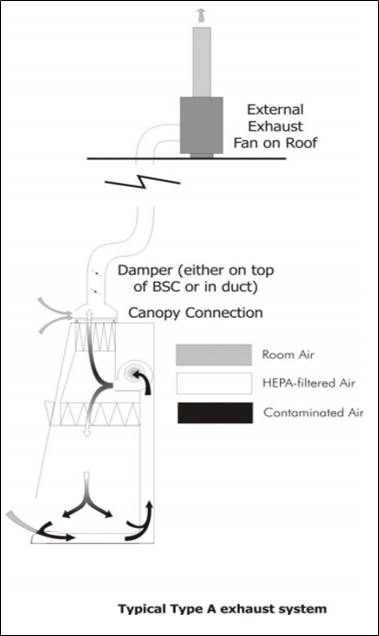

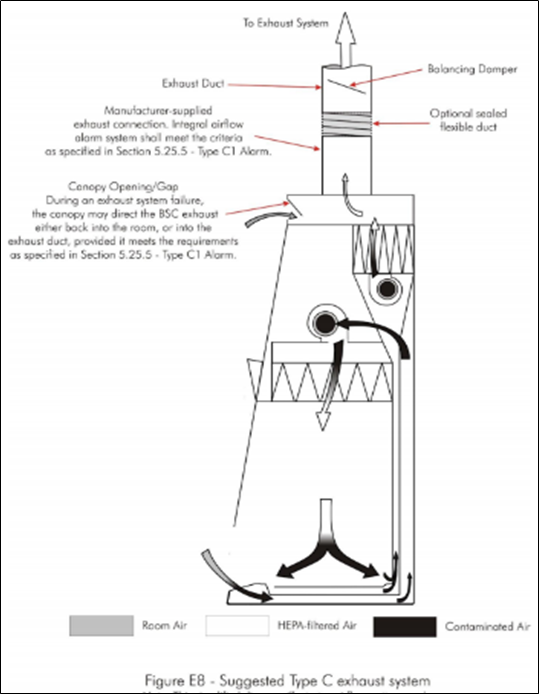

For a Type A Biosafety Cabinet fitted with a properly designed canopy connection, reduction or elimination of the exhausted air should not significantly affect the airflow patterns within the Biosafety Cabinet. Personnel and product protection of the Biosafety Cabinet will remain unchanged; however, chemical vapors generated in the Biosafety Cabinet will be exhausted into the laboratory via the openings or slots in the exhaust canopy.

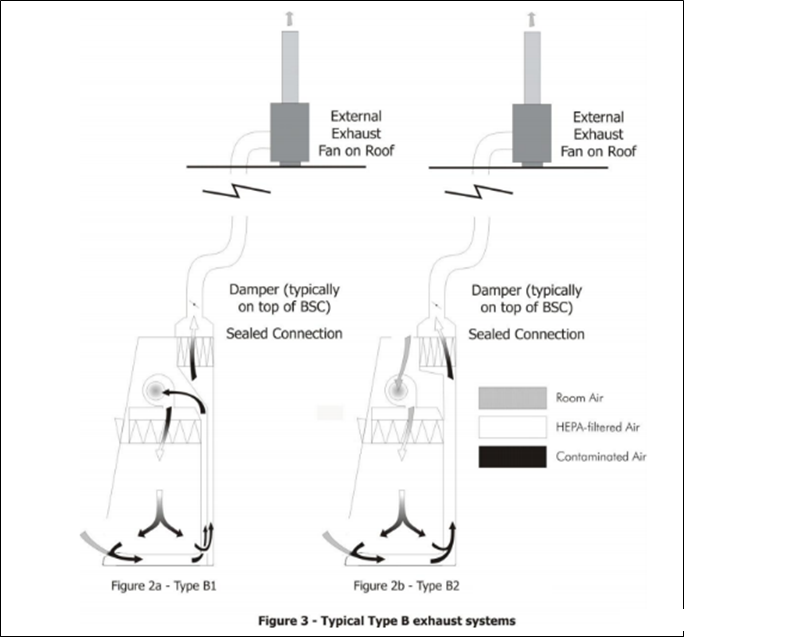

For a Type B Biosafety Cabinet, a significant loss of exhaust airflow will result in an alarm, turning off the cabinet blower(s). This stops the flow of air into the front of the Biosafety Cabinet (inflow), negating personnel protection, potentially allowing materials in the work area of the Biosafety Cabinet to escape into the laboratory.

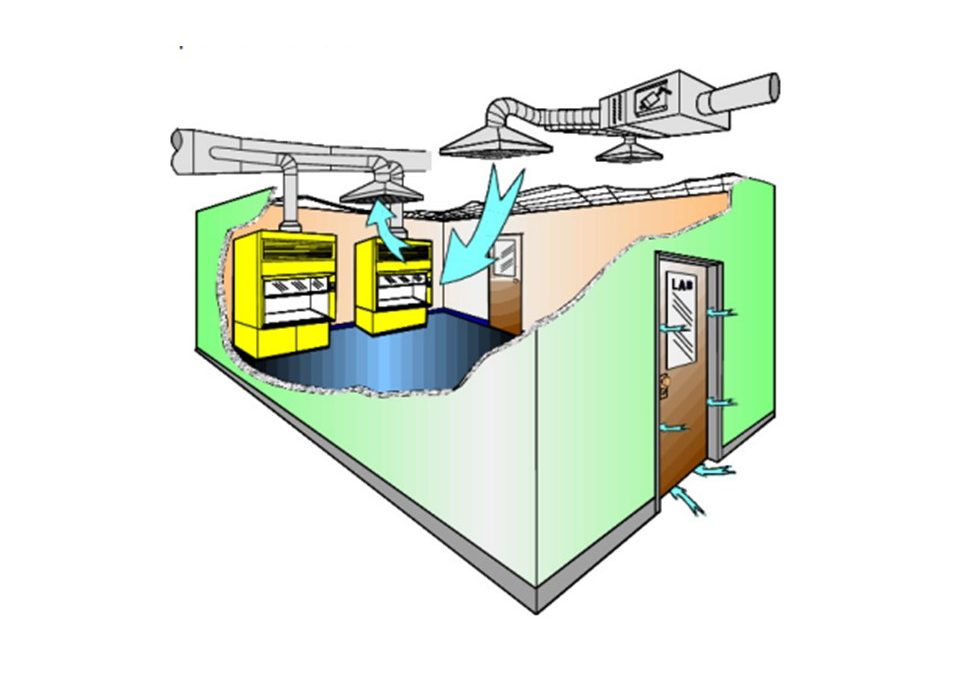

Canopy-connected Types A and C1 require a consistent, low static pressure. While a dedicated exhaust system is preferred, they may share a common exhaust system with other exhausted laboratory devices, if properly balanced. Type B Biosafety Cabinets require a higher static pressure that must increase as their exhaust filters load. They must be on a dedicated exhaust system, and not be ganged with other Type B Biosafety Cabinets, or other exhausted laboratory devices requiring a lower static pressure (e.g. fume hoods, canopy-connected BSCs). The exhaust system must minimize excessive lengths and elbows.

Recent Articles

- Gnotobiotic facilities: writing inside isolators 4 April 2022

- Germ-free cage sterilization 24 January 2022

- Microbiota and its importance in aging 25 October 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 2) 27 September 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 1) 30 August 2021

DVC – Digital Ventilated Cage for digital vivarium

The DVC® is capable to provide novel insights and enhance animal welfare checks thanks to the automatic data collection directly from the cage level. Specifically designed DVC® board enables different benefits for the researchers and vivarium people.