We left off last time with the following question: Which disinfectant should we use to obtain a decontamination of the external surfaces of the cage so as to ensure a low-risk management of the same once introduced inside the Biosafety Cabinet (BSC)?

What are the factors to consider when choosing the disinfectant? The list of these factors is relatively short: the disinfectant’s microbicidal spectrum, the concentration of the disinfectant, the required contact time, the degree of surface contamination (the microbiological burden we are dealing with), the compatibility with materials. When working with germ-free or flora associated animals the use of disinfectants with a very broad spectrum of action is required in order to obtain a decontamination that leaves no room for particular microbial forms (e.g. spores). This inevitably and significantly limits the classes of disinfectants available and will substantially spur us to use substances belonging to the group of High-Level Disinfectants (HLD).

In general, one of the advantages for this class of disinfectants is a reduced contact time and this feature meets our need to reduce the residence time of caged animals in static conditions. On the other hand, these disinfectants sometimes have chemical characteristics that make them not very compatible with many materials also used for the construction of Laminar Flow Cabinets. One of the least investigated factors, among those we have listed, is certainly the microbiological load of the surfaces to be decontaminated that can affect both the exposure time and the choice of the concentration of use of the disinfectant itself.

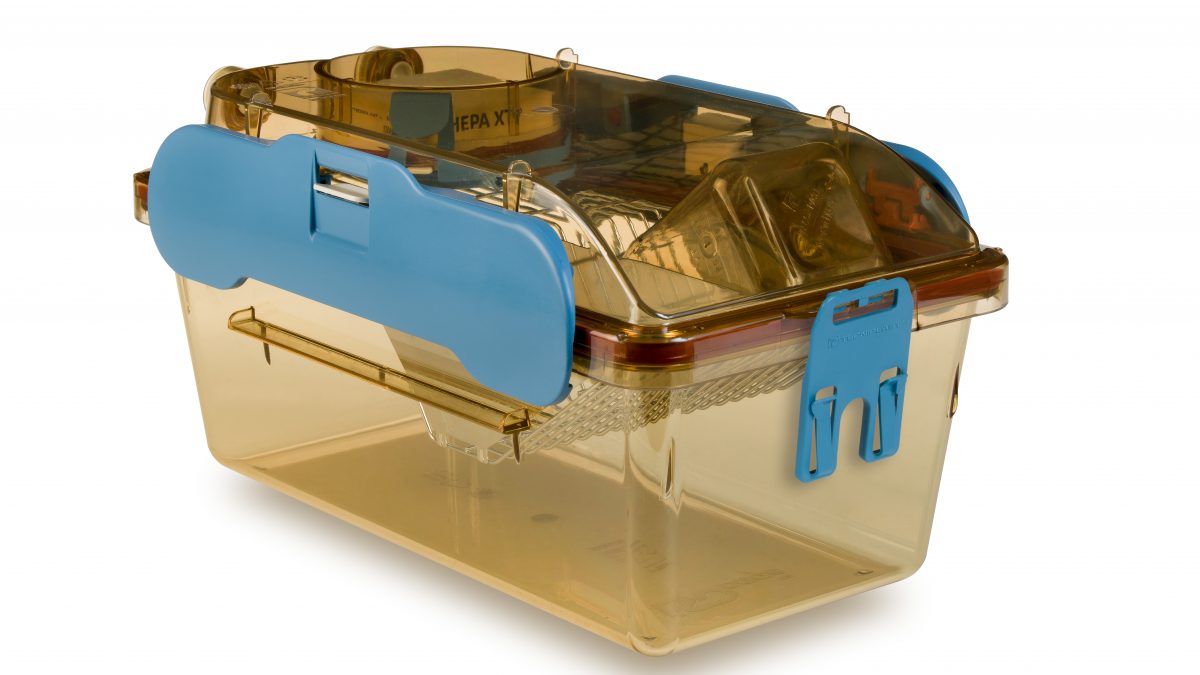

An attempt to compare two disinfectants with very different characteristics, but both with high decontaminating capacities was recently made at the Université Laval, Quebec city, Quebec, Canada1. The two disinfectants based respectively on sodium 26 dichloroisocyanurate (MB-10) and potassium peroxymonosulfate (Virkon™) were tested in order to adjust the soaking time of ISOpositive cages. In addition, the authors have compared “the microbial load on cage systems hosting mice for two weeks in axenic (AR) rooms and typical specific-pathogen-free (SPF) non-axenic rooms (NAR) to identify resistant microorganisms targeted for longer soaking disinfection as well as evaluate microbial concentration reduction procedures in AR”.

The identification of the “best” disinfectant to use at a gnotobiotic rodent unit in order to obtain efficient decontamination processes of the external surface of a high containment IVC is a process that requires multiple evaluations that lead to potentially different results in relation to local conditions (microbiological burden) and qualitative aspects of the local microbiology. The generalization of a choice of the type of chemical to be used is therefore arbitrary and could in some cases represent an unnecessary excess or, conversely, a higher risk solution.

1.Managing the Bacterial Contamination Risk in an Axenic Mice Animal Facility M. Lebeuf, N. Turgeon, C. Faubert, J.Robillard, E. Paradis, and C. Duchaine; Canadian Journal of Microbiology,12 April 2021; https://doi.org/10.1139/cjm-2020-0519

Recent Articles

- Gnotobiotic facilities: writing inside isolators 4 April 2022

- Germ-free cage sterilization 24 January 2022

- Microbiota and its importance in aging 25 October 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 2) 27 September 2021

- Procedural diversity and technical choices working with gnotobiotic mice in IVCs. (part 1) 30 August 2021

DVC – Digital Ventilated Cage for digital vivarium

The DVC® is capable to provide novel insights and enhance animal welfare checks thanks to the automatic data collection directly from the cage level. Specifically designed DVC® board enables different benefits for the researchers and vivarium people.